Table of Contents

- Introduction

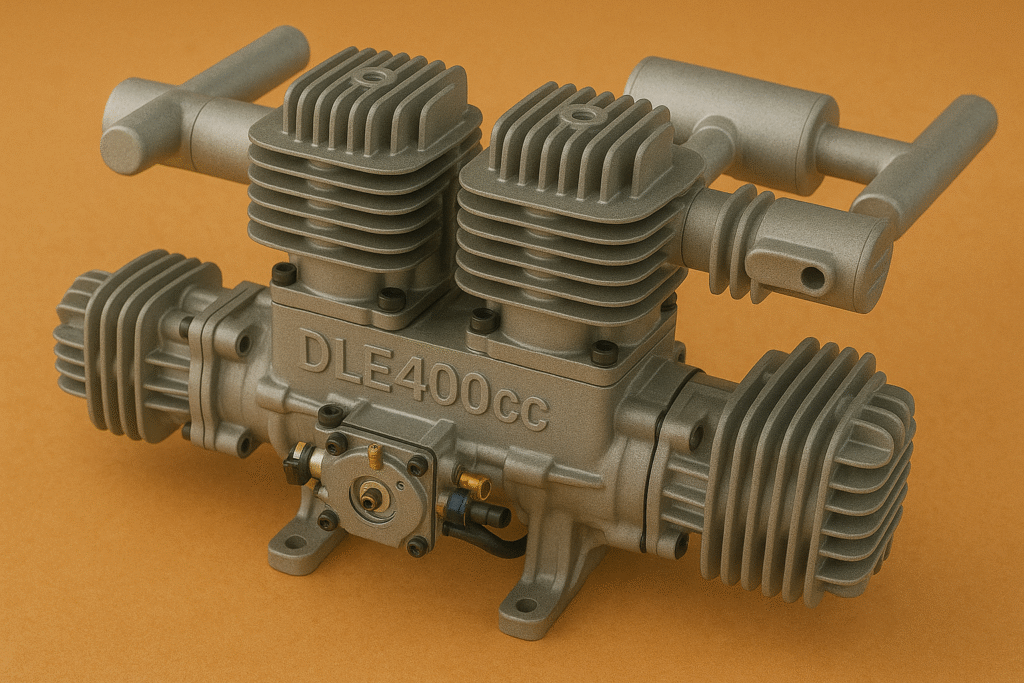

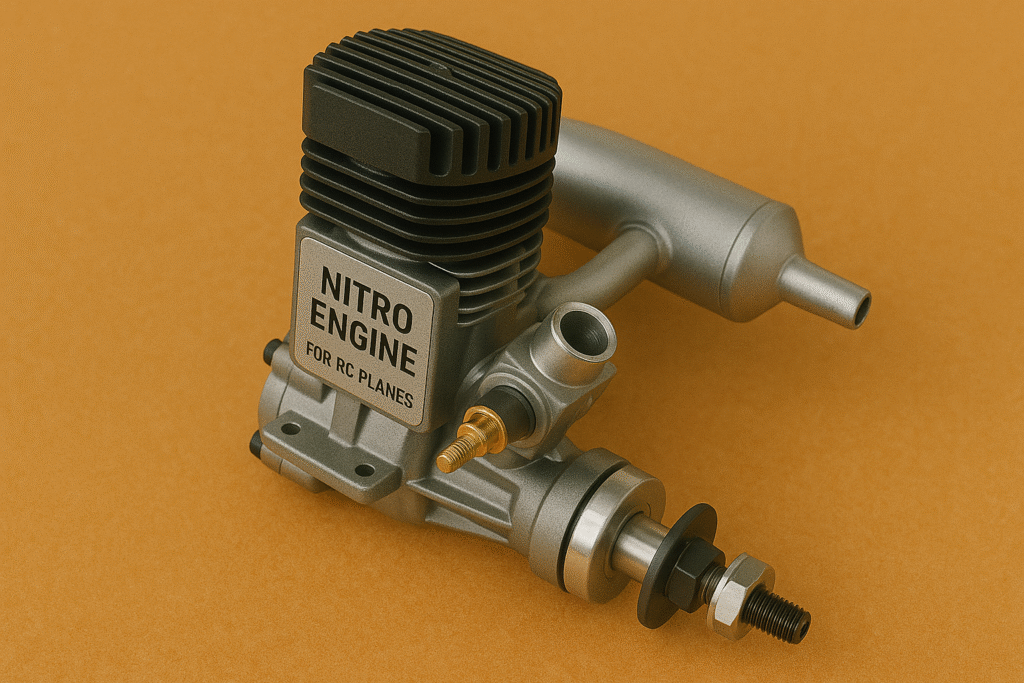

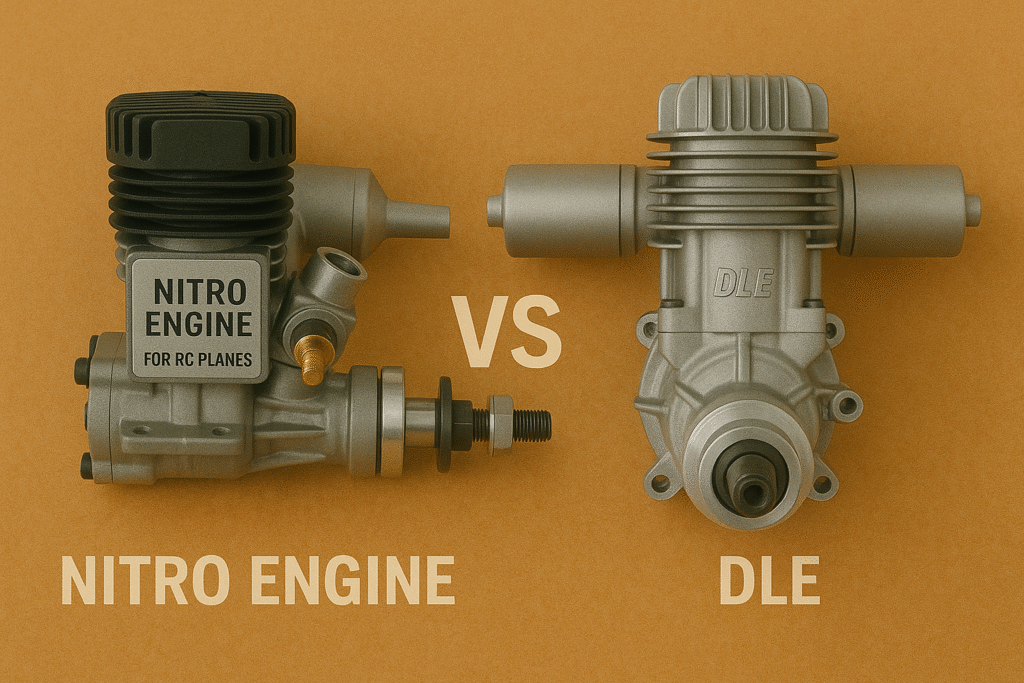

– Overview of nitro engines

– What to expect as a beginner - Getting Started and Setting Up the Basics

– Tools and supplies you need

– Priming the engine and glow plug check

– Pre-start inspection tips - Starting the Engine and Doing the Break-In Right

– First-time starting guide

– How to properly break in the engine

– Mistakes to avoid during break-in - Tuning Tips and Maintenance for Long-Term Performance

– Fine-tuning for speed and reliability

– Post-run care and maintenance routine

– Troubleshooting common issues - Conclusion

– Building confidence with each run

– Encouragement for continued learning

Setting up a nitro engine for the really first time may be both exhilarating and a little daunting, specifically if you’re new to the sport. But don’t worry—it’s easy than it appears once you get hands-on.

First things first, gather all that you need: nitro fuel (typically 20%), a glow igniter, the fuel bottle, a flat-headed screwdriver, after-run oil, and your RC model alongside a fully charged transmitter and recipient. Make sure your air filter is clean and installed appropriately because a dirty engine won’t last long. Connect the gasoline lines firmly and double-check for any leaks. Then set the engine by filling the tank and pulling petrol into the carburetor—this helps about the first ignition.

Test your light plug with the igniter; it should glow a solid orange. Once everything appears ready, you’re good to go to the beginning step. Be patient here—your engine might not fire up right immediately, and that’s entirely okay.How to Set Up a Nitro Engine for the First Time

Starting the Engine and Doing the Break-In Right

Once you’re set up, turn on your transmitter first, then your receiver. Attach the glow igniter and crank the engine using either the pull start or starter box. It might take a few tries, especially if this is the engine’s first run. After it starts, let it idle for a few minutes. For your very first tank, it’s best to let the engine run at idle with the car raised so the wheels don’t spin on the ground. This break-in step is really important—it helps all the moving parts settle in properly.

You want to keep the engine running rich during this time, meaning you’ll see some smoke coming from the exhaust. That’s a good thing! Run a few full tanks of fuel this way—start with idle, then gradually increase throttle as you go, but never go full throttle until you’ve completed at least 4-5 tanks. Let the engine cool down completely between each tank to avoid overheating. Don’t rush this step—it makes a big difference in how long your engine lasts and how well it performs down the line.How to Set Up a Nitro Engine for the First Time

Tuning Tips and Maintenance for Long-Term Performance

After the break-in time is done, you may start adjusting the engine for optimal performance. The idea here is to make tiny changes so the engine. It runs powerful without overheating. If your engine stuttering when growing faster, try modifying known as low-speed needles slightly. If it’s slow at full power, lean out the high-speed needle is used just a bit—but always check for smoke. You want a regulate between power and lubricant. Keep an eye on engine

temperature, and use a temp gun if you have one (target for roughly 200–270°F). After each run, don’t forget upkeep: maintaining empty the fuel tank, add a few drops of after-run oil, and clean an air filter. This procedure keeps your engine in great form and set for the next session. It’s also good to check the glow plug every now and then—they do wear out. Setting up and tweaking a nitro engine can seem like a lot at first, but once you’ve done it a few times, it becomes second nature. Take your period of time, enjoy the picking up process, and have fun with yourself nitro-powered machine!How to Set Up a Nitro Engine for the First Time